Protective Coating / Potting Technology

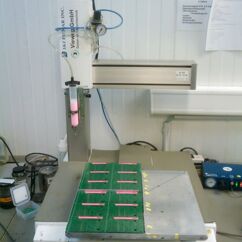

In the field of protective coating and potting technology,

STG-Beikirch processes your products with appropriate paints and potting components to protect them against possible environmental influences.

The required process auxiliary devices are developed and built by our designers and employees with a high level of expertise.

PCB Coating

We paint or cast your printed circuit boards on request.

The printed circuit board coating protects sensitive components from shocks and ensures a longer service life.

The protective coating protects electronic assemblies against humidity, condensation, corrosion-induced leakage currents or against surface contamination. The electrical conductivity of printed circuit boards that have not been treated by painting or potting decreases over time, e.g. due to various environmental influences such as oxidation or condensation. Electrostatically charged assemblies also attract dust particles that settle on the surface. We protect your printed circuit board by coating it with a special protective varnish.

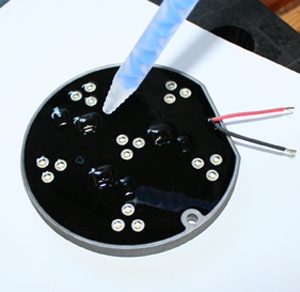

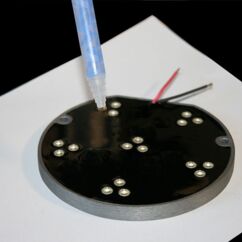

Potting

Potting technology is the application or coating of a liquid, 1 or 2-component encapsulating compound onto a confined printed circuit board or a housing until all components have been encapsulated. When the casting compound has dried and cured, all components are encapsulated.

The encapsulation protects the electrical circuit or cable connection from moisture, dust, contamination, vibration and shock. It improves electrical insulation, flame retardancy and circuit cohesion even during transport or installation in the field. At the same time, the heat dissipation of electronic components such as LED´s is improved. Potting systems must meet the highest physical and chemical requirements.

Transparent Potting

We can also cast transparent components for LED and other applications.

Vacuum Potting

Components that need to be protected from air and moisture are encapsulated under vacuum to ensure they are completely bubble-free.